Manufacturing companies face constant pressure to optimize production, reduce costs, and maintain quality standards. In today’s competitive landscape, manual processes and disconnected systems simply can’t keep pace. Enter ERPNext, a comprehensive open-source solution that revolutionizes how factories operate and compete in the digital age.

What Makes ERPNext Different for Factory Management?

ERPNext stands apart from proprietary manufacturing ERP solutions by offering enterprise-grade functionality without the enterprise price tag. This cloud-based platform integrates every aspect of factory operations into a single, unified system that grows with your business.

Unlike traditional ERP systems that require substantial upfront investment and per-user licensing fees, ERPNext operates on an open-source model. This means you pay only for hosting capacity, not for each employee who uses the system. For growing manufacturers, this pricing structure can save thousands of dollars annually while providing the same powerful features found in expensive commercial alternatives.

Core Manufacturing Benefits of ERPNext:

1. Real-Time Production Planning and Control

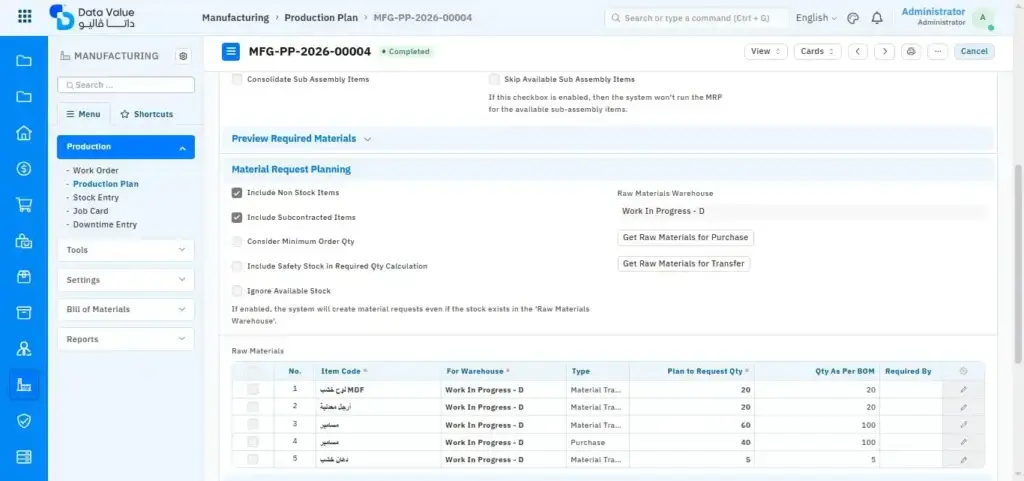

- ERPNext transforms production planning from a reactive scramble into a strategic advantage. The system’s Production Planning module considers multiple critical factors simultaneously: customer delivery commitments, raw material availability across warehouses, and current production capacity.

- When you create a production plan, ERPNext automatically pulls items scheduled for manufacture, fetches their Bill of Materials, and verifies material availability. This intelligent approach prevents production delays caused by material shortages and helps factories maintain on-time delivery rates above 95%.

- The Work Order functionality provides complete visibility into each production job. Supervisors can track progress in real-time, monitor which operations are full, and identify bottlenecks before they impact delivery schedules. This level of control reduces production lead times by up to 30% in typical implementations.

2. Intelligent Inventory Management

- Inventory represents a significant portion of working capital in manufacturing operations. ERPNext’s sophisticated inventory system helps factories strike the perfect balance between having enough materials to meet production demands without tying up excessive cash in stock.

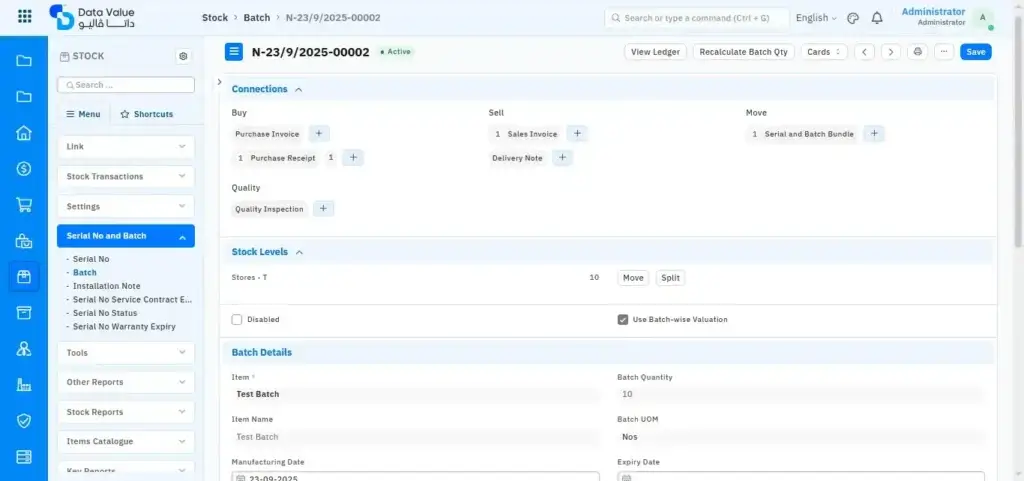

- The system maintains detailed stock ledgers that track every movement of materials, whether raw materials, work-in-progress, or finished goods. You can monitor inventory levels by warehouse, by batch number, and even by specific storage locations within facilities. This granular tracking eliminates the common problem of having materials somewhere in the factory but not knowing exactly where.

- For manufacturers dealing with perishable materials or products with limited shelf life, ERPNext’s batch tracking ensures first-in-first-out inventory rotation. The system alerts managers when batches approach expiration dates, preventing costly waste.

3. Accurate Bill of Materials Management

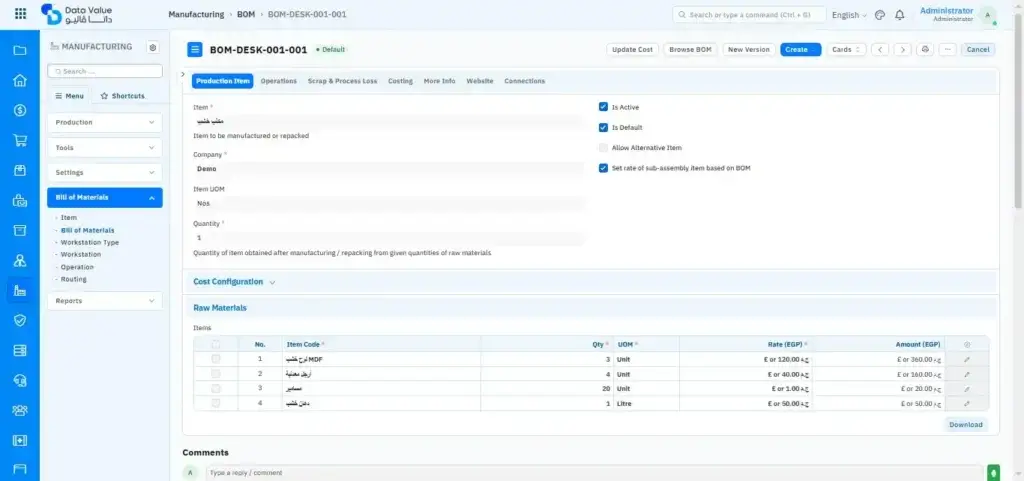

- At the heart of every manufacturing operation lies the Bill of Materials. ERPNext treats BOMs as living documents that evolve with your products. You can specify raw materials in different quantities and units of measurement while outlining the precise sequence of operations needed to transform them into finished goods.

- The BOM module excels at handling complex scenarios. For furniture manufacturers managing thousands of product variations based on finishes, fabrics, and dimensions, ERPNext uses item templates and variants to simplify catalog management. Instead of creating separate BOMs for each color of a chair, you define one template and multiple variants that inherit the base structure.

- BOMs also serve as powerful cost estimation tools. As you define materials and operations, ERPNext automatically calculates the estimated cost of finished items. This real-time costing helps sales teams quote competitive prices while protecting profit margins.

4. Comprehensive Quality Control

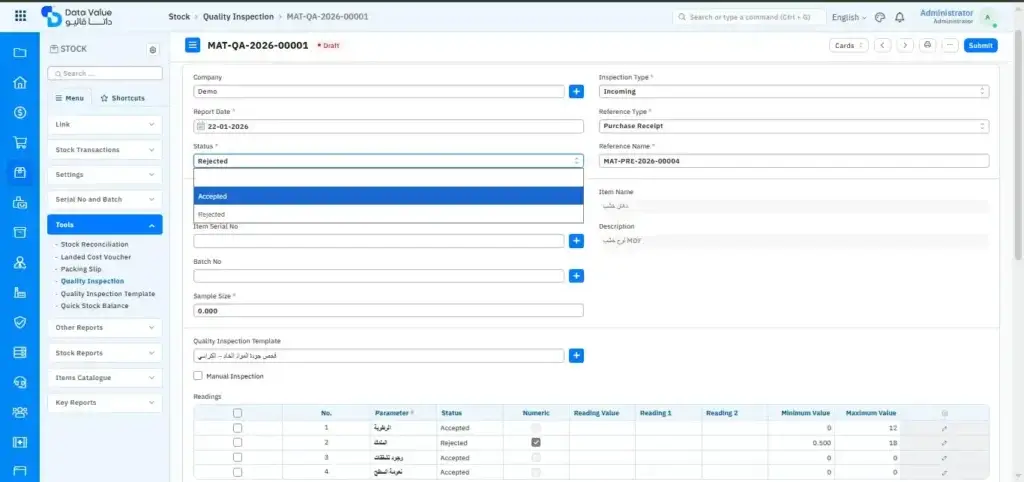

- Quality management in ERPNext begins before materials enter your factory. The Quality Inspection module lets you define acceptance criteria for incoming raw materials and finished products. Inspectors can record actual measurements and observations, with the system automatically determining pass/fail status based on predetermined tolerances.

- For regulated industries like pharmaceuticals or food manufacturing, ERPNext maintains complete traceability. Every finished product can be traced back to the specific raw material batches used in production. If a quality issue emerges, you can quickly identify all affected products and take corrective action.

5. Capacity Planning and Resource Optimization

- Factory equipment represents substantial capital investment. ERPNext’s capacity planning features help maximize return on this investment by preventing both overutilization and idle time.

- The system tracks workload across each workstation, enabling planners to schedule future production jobs efficiently. When creating work orders, ERPNext considers current capacity and alerts managers to potential overload situations. This forward-looking approach prevents last-minute scrambles and overtime costs.

- For factories running multiple shifts, ERPNext’s shift management integrates with the HR module to track employee attendance and ensure adequate staffing for production demands. Supervisors can see who’s present on each shift and reallocate resources as needed.

6. Integrated Financial Management

- Manufacturing profitability depends on accurate cost tracking. ERPNext connects production activities directly to financial accounting, eliminating manual data entry and reconciliation headaches.

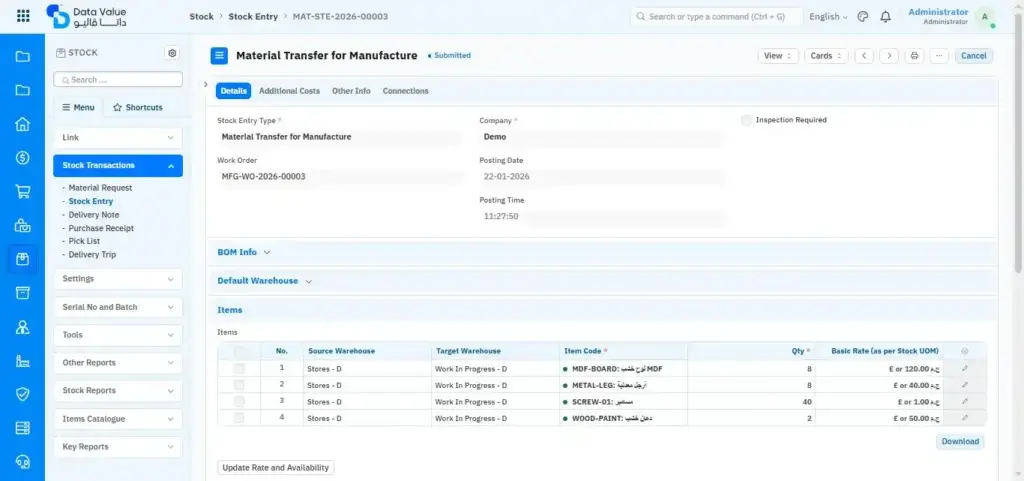

- When production consumes raw materials, the system automatically creates accounting entries that debit work-in-progress inventory and credit raw materials inventory. When finished goods emerge from production, ERPNext credits work-in-progress and debits finished goods inventory at the correct valuation.

- The system also handles complex costing scenarios. You can allocate manufacturing overhead costs like electricity, factory rent, and equipment depreciation to products using the Additional Operating Cost feature. This ensures your product costs reflect true manufacturing expenses, not just direct materials and labor.

7. Data-Driven Decision Making

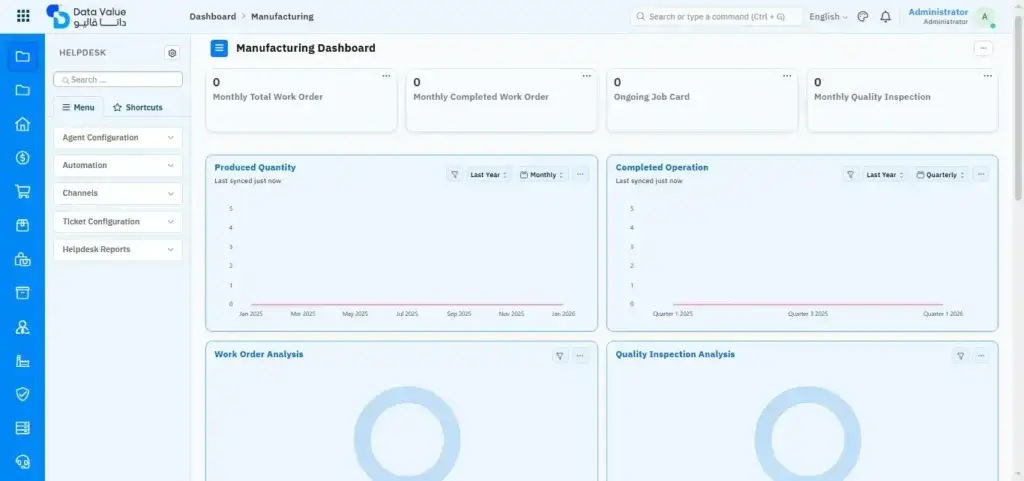

- ERPNext transforms raw production data into actionable insights through comprehensive reporting and analytics. The Manufacturing Dashboard provides executives with real-time visibility into key performance indicators: production efficiency rates, material consumption patterns, and quality metrics.

- The Production Analytics Report aggregates production status across all work orders, helping managers identify trends and make informed decisions about capacity investments or process improvements. Instead of relying on gut feeling, factory leaders can base decisions on concrete data about what’s actually happening on the shop floor.

Implementation Advantages for Factories

Scalability Without Linear Cost Growth

Traditional ERP vendors charge per user, meaning your software costs grow proportionally with your workforce. ERPNext breaks this model by charging only for computing resources. Whether you have 50 employees or 500, your software licensing costs remain controlled. This pricing structure makes ERPNext particularly attractive for growing manufacturers who need enterprise capabilities without enterprise budgets.

Flexibility Through Customization

Every manufacturing operation has unique processes and requirements. ERPNext’s open-source foundation and built-in customization tools let you adapt the system to your workflows rather than forcing your business to conform to rigid software constraints.

The Frappe framework underlying ERPNext provides low-code tools for creating custom fields, forms, and reports without extensive programming knowledge. For more complex customizations, you have complete access to the source code and a global network of implementation partners who can build exactly what your factory needs.

Multi-Location and Multi-Company Support

As manufacturers expand operations, ERPNext grows with them. The system natively supports multiple factories, warehouses, and even separate legal entities within a single installation. You can track inventory movements between locations, consolidate financial reports across entities, and maintain separate books for different jurisdictions.

For international operations, ERPNext supports over 100 languages and handles multiple currencies seamlessly. This global capability helps manufacturers maintain consistent processes across geographically dispersed operations.

Integration Ecosystem

Modern factories don’t operate in isolation. ERPNext integrates with the broader technology ecosystem through APIs and third-party connectors. You can connect IoT sensors to equipment, integrate with eCommerce platforms for direct customer orders, or link with logistics providers for shipment tracking.

The system’s open architecture means you’re never locked into a closed ecosystem. As your technology needs evolve, ERPNext can adapt and integrate with new tools without requiring a complete system replacement.

Real-World Impact on Factory Operations

- Manufacturers implementing ERPNext typically report significant operational improvements within the first year. Production lead times decrease as better planning eliminates delays caused by material shortages or capacity constraints. Inventory carrying costs drop by 20-40% as factories transition from safety stock to demand-driven replenishment.

- Quality improvements emerge from systematic inspection processes and complete traceability. When issues arise, factories can identify root causes quickly and implement corrective actions that prevent recurrence. This systematic approach to quality reduces scrap rates and warranty claims.

- Perhaps most importantly, ERPNext provides the visibility and control that manufacturing leaders need to make confident decisions. Instead of wondering about production status or material availability, managers access real-time information that reflects current factory conditions.

Getting Started with ERPNext

- The ERPNext implementation journey begins with understanding your current operations and identifying weaknesses. If you are a medium or large factory, ERPNext is an ideal starting point. For more complex operations or those requiring extensive customization, ERPNext’s global partner network offers implementation services.

- The system can be deployed in the cloud for rapid implementation and minimal IT infrastructure requirements, or on-premises for manufacturers with specific data security or compliance needs. Hybrid deployments combine cloud convenience with on-premises control over sensitive data.

- Training requirements are modest compared to enterprise ERP systems. ERPNext’s intuitive interface and comprehensive documentation help employees become productive quickly. The active community forum provides answers to common questions and best practices learned from thousands of implementations worldwide.

Conclusion: The Future of Factory Management

Manufacturing competitiveness increasingly depends on digital capabilities. Factories that continue relying on spreadsheets and disconnected systems find themselves at a growing disadvantage against competitors leveraging integrated ERP solutions.

ERPNext democratizes access to world-class manufacturing software by eliminating the cost barrier that historically kept advanced ERP out of reach for small and mid-sized manufacturers. The result is a more level playing field where operational excellence matters more than IT budgets.

Contact us today for a personalized demonstration and let us show you how ERPNext can transform your factory operations, improve profitability, and compete effectively in the digital age.

ERPNext offers a proven path forward. Its comprehensive functionality, flexible customization, and sustainable economy make it the ideal foundation for manufacturing excellence.